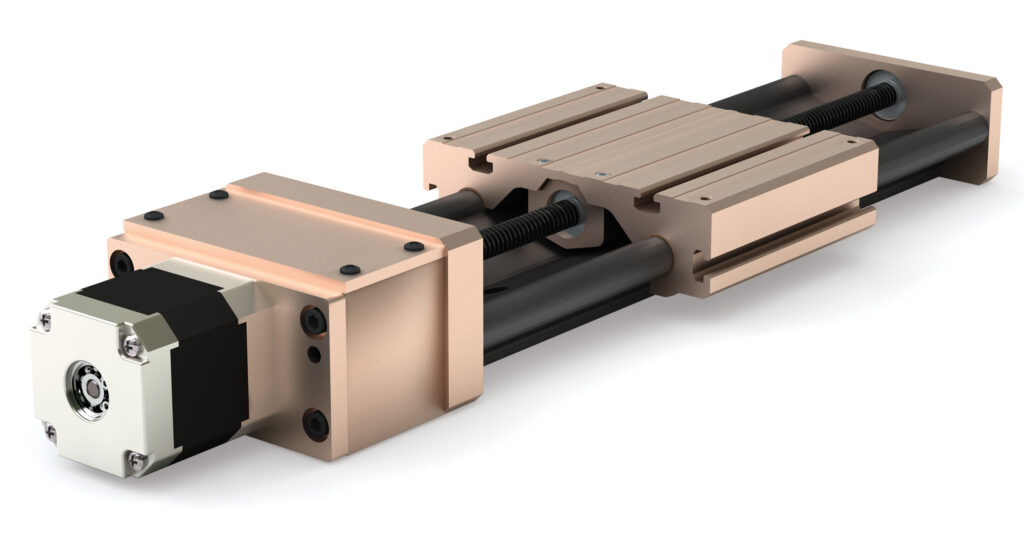

Linear guide rails are a system of rail and blocks that supports the motion of things. They are excessively used because of their rigidity, travel accuracy, and load capacity. These rails can withstand both liftoff and downward loads and also moment loads. In addition to this, linear rails allow a longer travel length compared to the other guides. Not only this, but you will also get a better load characteristic. So it will be beneficial for you to go with the best option.

tuli-shop.com has a range of linear guide rails at quite a reasonable price tag. They also sell ball bearings, if you need them separately.

Page Contents

How do they work

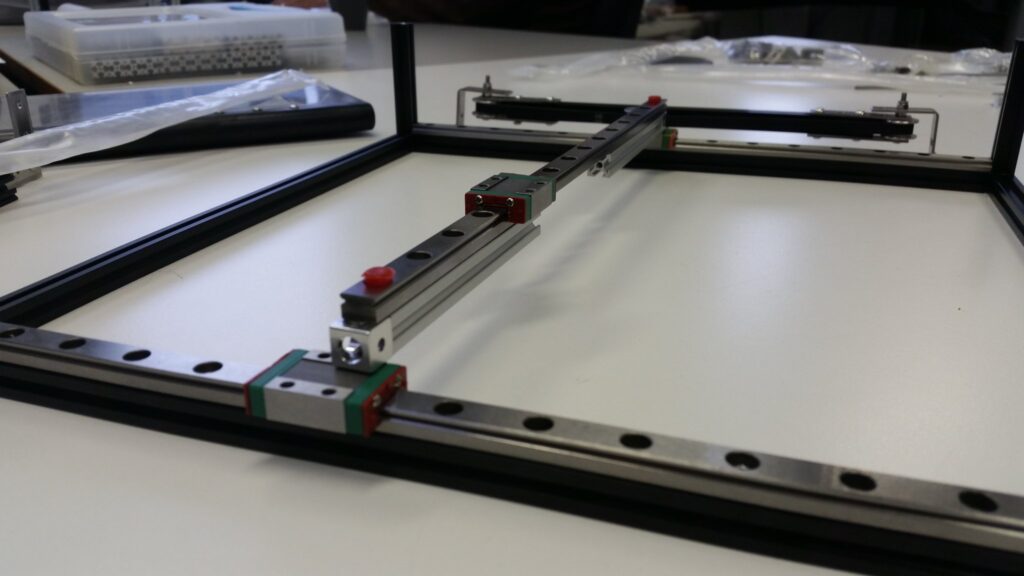

As mentioned above this system consist of two parts, one is the rail and another one is a block. The block moves along the rail in a forward and backward motion. You have to mount the linear block to the weight bearing block and connect it to the moving components. This supports the movement for any component. There are recirculating ball bearings on the blocks that make it easier to move the blocks along the rail. That’s how they move without much effort and make your task quicker.

Two types of linear guide rails

Various applications use two types of linear rails. One is a single rail and the other is a dual rail. Single rails save space and prevent any possible misalignment among the different components of the system. Furthermore, they can also hold overhung loads too. On the other hand, Dual rails are simply a pair of a single rail. They become useful when you need to resolve the moment load on the bearing blocks.

Applications of linear guide rails

The different applications of linear guide rails include;

1. Linear actuators

These actuators use the single rail system. Actuators are drive with pneumatic cylinders, screws and belts. As the single guide system can withstand moment load, it is successfully used for the actuators. In addition to the load-bearing capacity, the guide system is also quite fast and can travel at up to 5 m per second. Therefore, it is quite helpful for pneumatic and belt-driven systems.

2. Overhead transport system

It also works by the single guide system because the load is centered below the bearing block and rail. The overhead transport system requires a guide rail that can withstand heavyweights. Thus, through the linear guide rails, you have the best choice because it can withstand heavyweights. Furthermore, it can also transport things at super-fast speed. In addition to this, the rigidity factor also makes it the best choice as it will help the stiffness of the whole system.

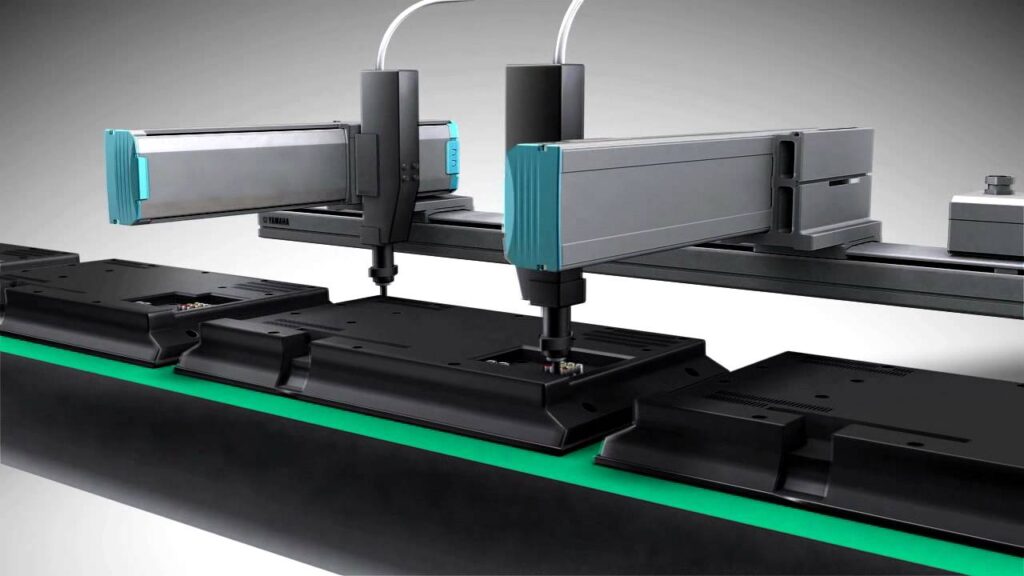

3. Gantry robots

Robotics also involve quick and precise movements. Gantry robots work along 2 X-axes but sometimes there are also 2 Z and 2 Y axes. Thus, because of the individual axes, the single guide rail system is the best choice. Therefore, the guide works by the pulley, belt and screw system.

4. Linear stages

Stages are actually high precision systems and therefore, very high travel accuracy is required. In addition to the high accuracy, a very minimal deflection is also an essential requirement. In Stages, the load is usually centered on the stage with almost no moment loading. Even if there is moment loading, it is very little. Therefore, the best choice is to use the dual linear rail system as it ensures stiffness. Furthermore, it also offers a maximum bearing life so it remains useful for a longer time.

5. Machine tools

Machine tools also require a high level of accuracy and also stiffness during traveling time just like the Stages. Travel accuracy (that too at a high level) is essential to ensure that the best quality products are produced by them. Therefore, to achieve this, machines have to minimize deflection.

So, to do so, you have to use two rails. This will ensure that two bearing blocks remain on each rail. This increases efficiency and also decrease deflection. Furthermore, machine tools have to experience heavy loads and that decreases their service life. That is why, through the two rails, the overall weight will divide on the 4 bearing blocks. As a result of weight resolution, the bearing life maximizes many folds.

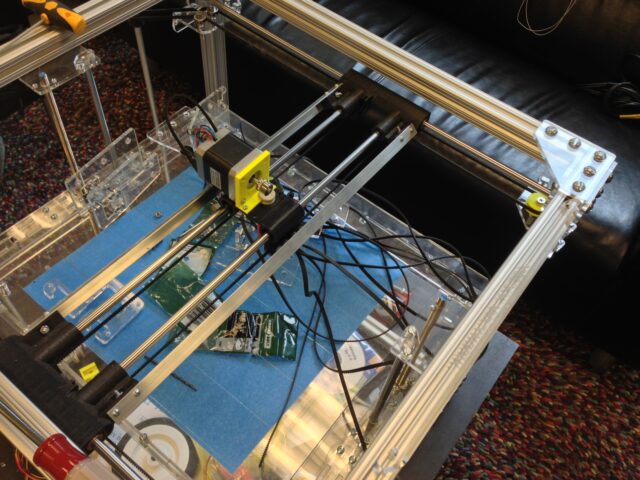

6. Cartesian robots

Unlike the gantry robots, the Cartesian robots require one linear system on each axis. Therefore, you have to ensure that every axis can bear a heavy moment load. In addition to this, the axes of Cartesian robots are built from linear actuators. These actuators use 2 linear guides that are in parallel alignment. That is why Cartesian robots use dual-rail actuators.

7. Robot transport units

Robot transport units are also known as the 6 axis robots because of their movement in multiple directions. They provide a flexible motion for different applications (for the ones that need rotation and movement in several directions). In addition to the six axes, the dual rail system can also allow movement in the 7th axis. Thus, the robot can transport the materials to a completely new location. This increases the working efficiency of the robots and makes transportation quick and easier. Moreover, the robot can also join multiple rails and in this way, it can travel very long lengths. The transportation length can even exceed 15 meters.

Advantages and disadvantages of using the linear guide rail system

Advantages

- It is highly durable and can bear a range of loads for various applications.

- The system has very little friction issue because of the ball bearing movement system.

- It offers high accuracy of the blocks.

- These Rails offer equal load-bearing capacity in all 4 directions.

- It also offers high rigidity.

Disadvantages

There are not many disadvantages to using this guide system. The only bottom line is that it is not much effective in terms of vertical applications. But this is only because it is a linear guide rail system and not the vertical one.