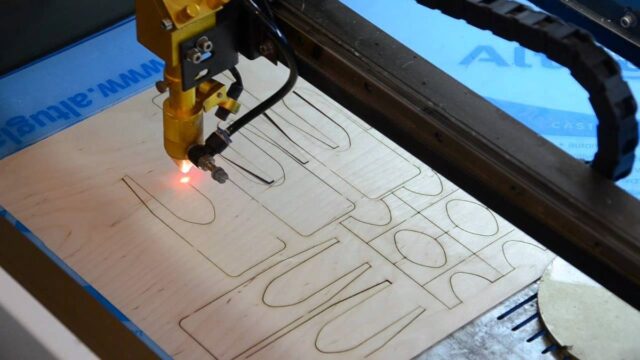

Being an engraver is an interesting choice for a career, don’t you think? We are certainly not talking about the profession that is simply not as common in this day and age. However, that doesn’t mean that you shouldn’t consider this to be a step further in your career. We are not talking about a simple profession.

The reason is quite simple. We are talking about a profession that requires a lot of knowledge on your behalf. Therefore, you need to start educating yourself for a long time before you are competent enough to say you are a competent engraver. Also, it is important to have enough practice.

Not to mention that you will need to purchase a proper co2 laser cutting machine. For example, we can see that not all the materials out there can be cut with these. That’s why we want to provide you with a couple of materials that cannot be cut with laser cutters for many reasons.

Without further ado, let’s take a look at some of these.

Page Contents

1. Plastic

The first material we want to discuss is plastic. We are talking about the material that already requires careful handling due to its characteristics. It needs to be said that you shouldn’t treat it with a laser cutter. Certain types can be treated with these, but it is a no-no for the vast majority.

The reason why you shouldn’t use later cutters for cutting these is that they consist of certain chemicals that can simply evaporate during the procedure. The evaporation of these chemicals will make the material’s quality significantly lower, which can determine the quality of the end product, right?

Also, the person who works with this material should know that these chemicals can be quite damaging to your health. Naturally, this is not the only material that releases these chemicals. Still, we can say that this is probably the commonest one. Also, be careful even with your work on less damaging types.

2. Polyvinyl Chloride

Without any doubt, all people have heard about polyvinyl chloride or PVC. We are talking about the material that is used mainly for plumbing. However, that doesn’t mean that it cannot be used for many other purposes. Once again, this is a material that releases harmful substances while they are cut with a laser.

Probably the most harmful substance released as a result of this procedure is chlorine gas. Plus, this is not something that can harm human health, it can also prove dangerous for the machines themselves. On the topic of human health, it is clear that the lungs are the organ that’s most vulnerable to this chemical.

Some would say that this can be done by using some protective gear. However, we wouldn’t say that this is a good idea since it can inflict a big problem on the chunk you want to work on. That’s why we would recommend you to use different devices, like an electric saw, to cut polyvinyl chloride.

3. Metals

Another material you shouldn’t use in these procedures is metals. As we all know, it is possible to treat a wide array of metals with these machines. There are some limitations when it comes to these since not all of them can be cut. Instead, it is possible only to engrave them.

Since it is not likely that you can use these properly, we would recommend you to ask around about them and see which ones are possible for cutting. Also, we believe that not all the machines are capable of conducting an effective procedure of this sort. Have that in mind when you choose the machine.

So, we wouldn’t recommend you to look at some cheaper ones. When it comes to the metals you should be aware of, there are a couple of them. We are talking about metals like chromium and cobalt. You can engrave them with some less capable devices, but it is not possible to cut them efficiently.

4. Plexiglas

Polycarbonate or Plexiglas is another material you shouldn’t cut with laser cutters. It’s because this is a durable material that is used in the automotive industry. Since it can sustain quite a lot of pressure inflicted by practically all the devices out there.

So, it is not possible to cut it with a laser cutter. It is not only hard enough to sustain physical pressure, it can sustain acids, heat, and gasoline.

Another significant thing to point out is that you can use it for protection during this process since it can help with absorbing the radiation that comes out as a result of the procedure. So, you can see that it is not possible to cut Plexiglas this way. It isn’t worth it to try it out as it is.

5. Food

Last but not least, we would like to discuss an interesting case. In the last couple of years, we can see that many people were advocating for using laser cutters for cutting food during production. However, recent studies have shown that this shouldn’t be done at all for many reasons.

Before these were published, we couldn’t see that laser cutters tend to produce certain substances, which can contaminate the food. Therefore, it is not possible to use it for consumption. Among many of these substances, you will find wood smoke and acrylic smoke. So, it should be avoided completely.

That doesn’t mean that there are no specialized laser cutters that can be used for cutting food. Naturally, using these for engraving and cutting rough materials is not possible since they are simply not as strong. Also, they do not produce any substances and chemicals that contaminate food.

The Bottom Line

Using laser cutters is quite an efficient way to engrave and cut through many materials. Still, you cannot count that all materials out there can be processed this way. In this article of ours, you can take a look at some of these. By understanding this, you can avoid wasting both the time and money you can spend on choosing the material.