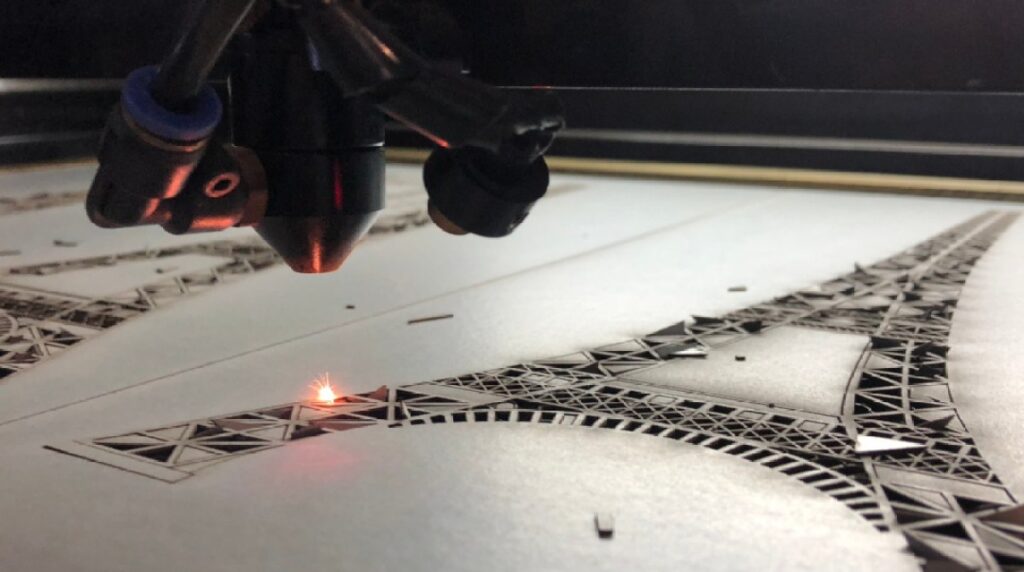

The manufacturing process grows simultaneously with the development of technology. After all, the whole point is to boost fabrication, to make it faster, and facilitate the entire process with the goal of increasing the production and the number of items. Nowadays, laser cutting machines are an essential tool used in the modern production of goods.

These have made a revolution in this line of business, so the fact that they are widely used today comes as no surprise. This is due to the numerous advantages and benefits they can provide. So, in the following article, we will introduce you to some of these and give you a list of reasons why you should own one of these.

Page Contents

1. Accuracy

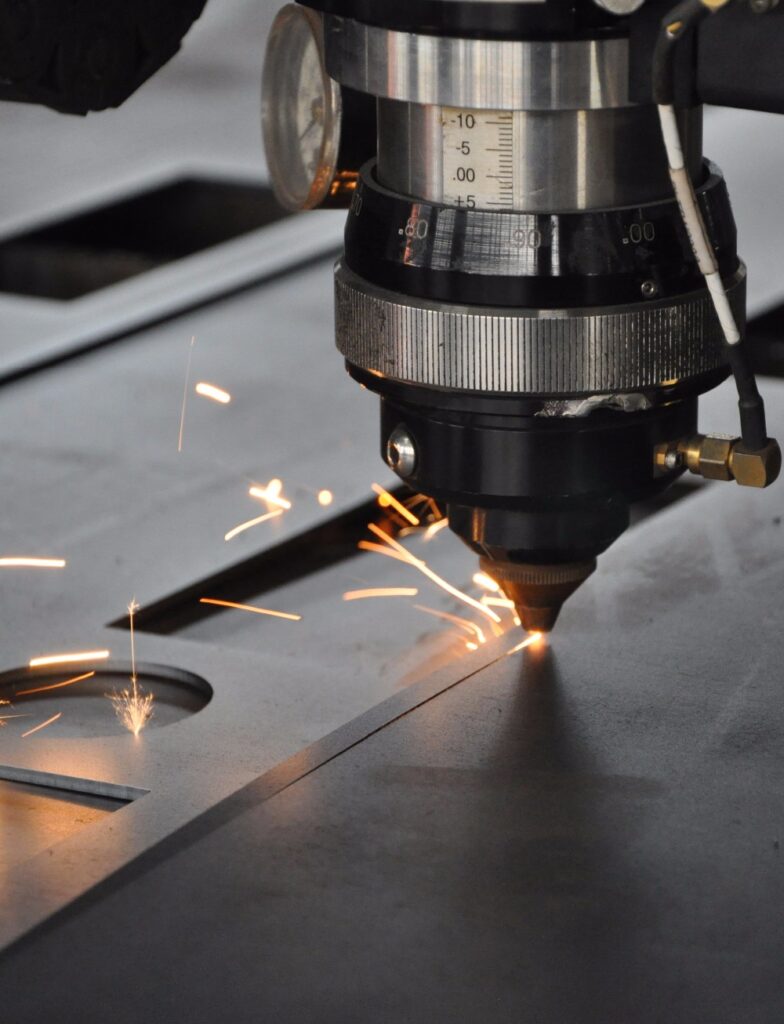

The first and some would argue the most important advantage of using this machine is its accuracy. When it comes to mass production, it is crucial that each item is manufactured perfectly because otherwise, their quality would be anything but high.

What’s more, by having a tool that enables you to create a piece every time will also save you a lot of money. How? Well, simply put, it won’t be necessary to do any additional work or use other tools, which won’t only save you and your employees a significant amount of time, but also funds since you won’t have to invest in additional pieces of equipment.

2. Flexibility

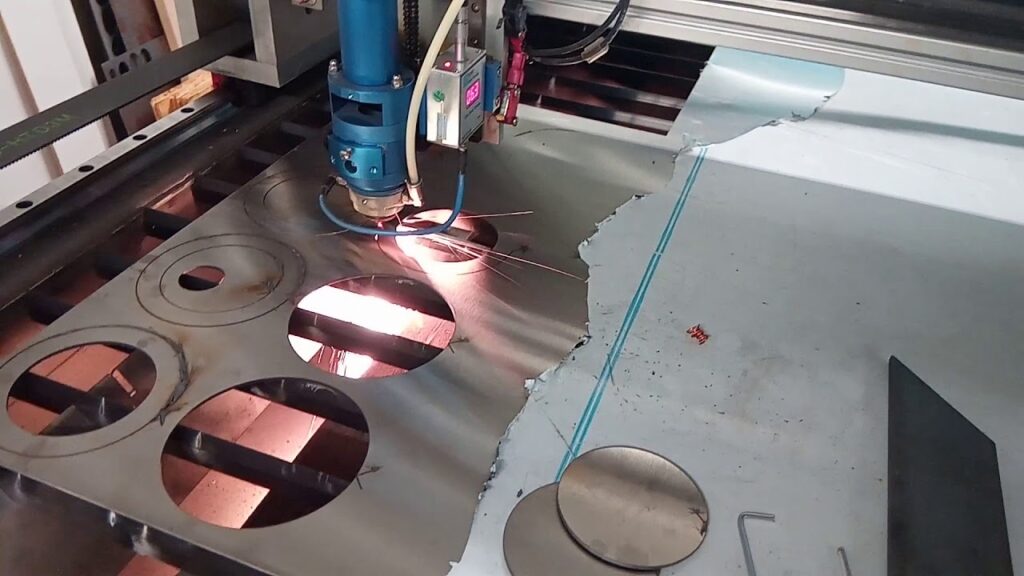

When working on intricate designs, you would be required to use different types of tools to reach your main goal. Well, when having a CO2 laser cutting machine, this isn’t necessary. Basically, you can use this tool to cut any shape you need, which is very convenient, you must admit. The same rule applies when it comes to engraving. We have already mentioned this machine’s accuracy and the significance of it, so just try to imagine how much time you will save using the same tool. All you have to do is input new instructions and witness the change. If you want to learn about the different features that this tool has, check this page.

3. Reproducibility

Once again, if you are mass producing any kind of items, their quality isn’t the only thing you have to worry about. You should also ensure that they are all the same, that is, that they can be observed as replicas of one another. This is exactly what this machine allows you to get.

Due to the fact that it is precise and flexible, you will get perfect pieces every time. The difference between the items will be minimal, so it is definitely something that can be disregard.

4. No manpower needed

When you implement this laser cutting machine into your production process, you will eliminate the need for manpower, or at least minimize it. The machine does all the work on its own. As already mentioned, all one has to do is program it and maybe stick around to ensure that it functions properly.

Nevertheless, this cannot come in comparison to the traditional process from the past. First of all, you will save a lot of money since you will be able to cut down the number of people you need in your factory. Secondly, you can provide your current employees with more benefits since you will have more funds at your disposal. Finally, they will be able to focus their efforts on some other parts of the production process. They won’t have to lose time overseeing something that can be done by a machine, but instead, they can work on creating new designs or coming up with ideas on how to improve the business and grow your company.

Additionally, you will almost completely eliminate potential injuries. This was a significant problem in the past because accidents occurred, no matter how trained and careful the employees were. When it comes to this machine, as already mentioned, the workforce is needed only to supervise it, and of course, to do repairs when needed. This doesn’t mean that you should invest in training people on how to use the machine properly, but the chances of injuries happening will be significantly lower.

5. Avoid damages

Generally speaking, when using some traditional tools to cut materials, there will be some sort of damage once the process is done. To some people, these marks can seem insignificant, but you have to agree with us that they can greatly affect the quality and aesthetic appearance of the merchandise. When this occurs, employees would have to use additional tools and techniques to remove these imperfections.

One more time, due to the previously described features and benefits of a laser cutting machine, these marks won’t occur. What’s more, the machine itself never comes in direct contact with the item, so it isn’t possible for any kind of damage to appear. As you can imagine, this is another advantage that will save you time that you would otherwise waste on cleaning.

Furthermore, when cutting metal, some machines would melt the material due to the high temperature they use. That’s right. This is another issue that won’t occur when using a laser one because the heating area is quite small, and plus, the machine doesn’t come in contact with the metal, so it is impossible for it to damage it this way.

6. Use it on different materials

Nowadays, most merchandise consists of different types of materials. Naturally, this isn’t always true, but it is in most cases. What does this mean for manufacturers? It means that they have to invest considerable funds into different pieces of equipment, one for each material they use. However, this is not an issue when it comes to laser cutting machine.

It can be easily programmed to cut through different kinds of materials. Obviously, this is something that mainly depends on the power of the one you purchase, which is why we believe that a high-quality and powerful one is worth the investment.

In addition, don’t forget that these lasers can be used for engraving as well. That is another task you will be able to complete with a single tool, without using any others.