Heat press transfer printing also referred to as thermal printing, thermal transfer printing, and thermal-wax transfer, uses heat to transfer the candle’s image to the object. Thermal-printing-based methods work with pre-printed photos on a single sheet of wax.

It is also being used for producing the printed image-on-the-fly created by layering wax dye to an object. Heat transfer printing can replace or augment alternative printing techniques. This method is done with the help of a heat press machine. You can explore the latest heat press machine on heatpressreview.net if you really want to get detailed specs and working of these t-shirts printers!

Page Contents

Materials for Transfer Printing

A heat-transfer printer needs a type of wax-based ink ribbon to create the image. The printer works by pressing the tape against the printing object and heating the opposite side until melted ink from the ribbon and transfers it to the item.

Wax-based ink ribbon can work in two ways depending on the printing process. Print the desired image can be signed into ribbons wax and applied through heat press and pressure directly. Alternatively, the printer can use the four ribbons – in cyan, yellow, magenta, and black. It is used to draw an image during the printing process by layering colors on the printed surface.

Novelty Fabrics and Materials

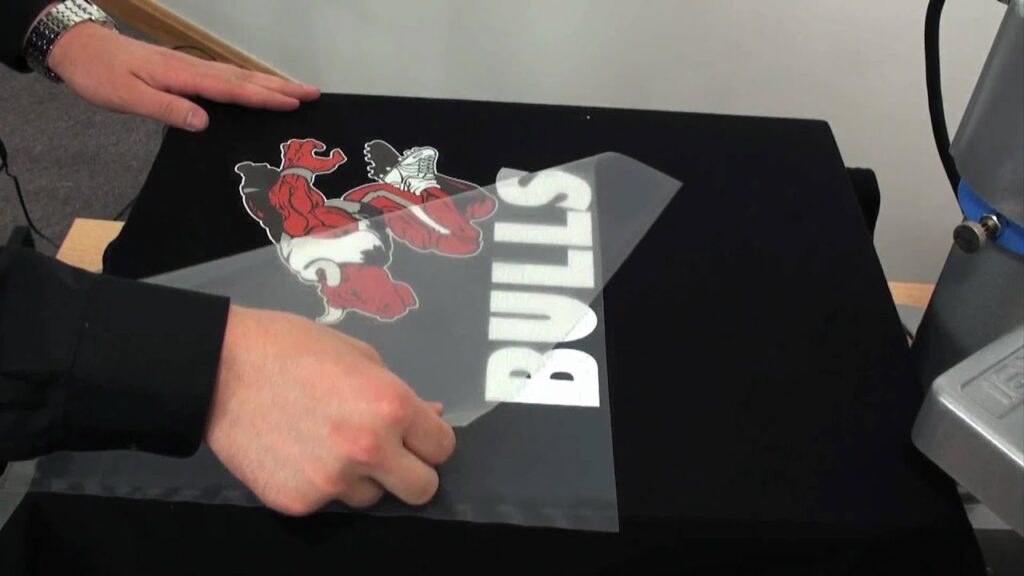

As his colleague inkjet, thermal transfer printing works well on paper. Still, it excels in applying the images to various materials that include garments and textiles—for example, the heat-press maker T-shirt transfers pictures to a piece of cloth. Heat transfer printed image durable, heat resistant, and waterproof adhesive.

Direct thermal printing is a heat press type of printing that burns images to objects on heat-sensitive materials. A direct thermal printer does not require any ink or wax to create a photo; instead, they use a coated paper that changes from white to black when heated.

Classification of Heat Press

If we take the T-shirt printing, for example, a print T-shirt with heat transfer printing can be generally classified into three categories:

1. Sublimation Printing:

Applicable on dry fit, microfiber, jersey, polyester, quick-drying T-Shirt, and materials coated surfaces such as coated mugs, plates coated, etc. Sublimation involves a heat press printing machine, sublimation ink, and paper usage in the printing process.

This transfers sublimation ink on the fabric by high temperature and pressure within 1 minute. Sublimation T-shirts would typically leave the permanent, vivid image with shades of soft-to-the-hand.

2. Transfer Printing:

Applicable on any tee fabrics such as cotton, polyester tees, caps, etc., in every color. Transfer printing using pigment ink and transfer paper in the heat press printing process.

There are two kinds of light transfer paper-based to a white T-shirt and dark based on the T-shirt color. We use the original transfer paper for better print quality while using a digital heat press.

3. Vinyl Printing:

Effective on vinyl transfer films such as Flock, PU, Glitter, Glow in the dark, reflective material, and hologram. Vinyl printing is limited to only one color printing whereas the mini heat press is the choice of most users in this regard.

The artwork was designed in the software; then, the line will be sent to the vinyl cutter or plotter to cut. After cutting, we remove unwanted vinyl from the original vinyl transfer film; then, it is ready for heating for your fabric.

What Equipment & Supplies Needed for Heat Transfer Printing?

Heat press transfer can be achieved through several different methods, but to this page, we will focus on commercial applications for heat transfer printing heat transfer DIY contrary to what you can do at home to iron. Here’s what the expert’s heat transfer uses to implement your company’s logo with your product through a heat press machine:

Computers – laptop or computer with graphic design software are required to create a custom design that will be printed on heat transfer.

Printer – a printer used for the heat press application is usually more significant than the average printer with a fair margin to accommodate larger designs. Aside from the size, the printer is used for heat transfer function similarly to a standard inkjet printer, only with different ink and special transfer paper.

Ink – there are several types of ink used in printing heat transfer to achieve different finishes. Inkjet ink is the most commonly used because it is the most affordable and accessible type of ink. Pigment inks are also used for fade resistance, and sublimation ink is used to print dye sublimation.

Heat Transfer Paper is a special paper designed for heat transfer and typically wax and pigment coated polymer films, making a permanent bond with the fabric fibers when heated. Transfer paper naturally comes in 13 “by 19” sheets of deals increase freedom of design.

Cutter – vinyl cutters used to cut paper design of the transfer to be applied to the substrate.

Conclusion

Heat press comes in several shapes and sizes depending on the heat transfer applications. Direct thermal and thermal transfer printing are both commonly used to make labels and receipts. Recommended heat transfer printing on direct thermal printing for labels and papers that need to last more than half a year, but the direct thermal printing is cheaper and requires only one stock of material for printing.