We can notice that 3D printing and some other advanced systems became a trend in recent years. It is not a surprise since they are providing higher efficiency and accuracy of production. These modern systems are all based on the process that is present for a longer time, which is related to CNC machines.

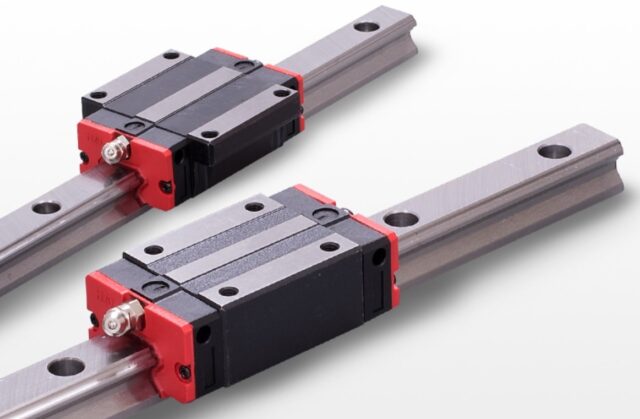

The purpose of these machines is to provide outstanding efficiency for manufacturing lines, and the system is using linear guide rails to achieve strong performances.

This technology represents a revolution in production since you can apply setting with computer, and the machine will deliver the provided measures on some material or surface. Linear guides are used for improved precision and flexibility.

There is a great selection of linear guides available on the market today, which you can find here. If you are not using how to make the right choice when buying this product, we are going to introduce you to some of the most important things that will help you find the best solution.

Page Contents

1. Design

Before you buy any type of this equipment, it is essential to determine what you are going to create with a CNC machine. In that matter, you should work on the project and create a sketch that you will apply to the software, and then buy suitable linear rails. Keep in mind that making a mistake here could lead to a lack of flexibility and the ability of the machine to create a particular part or product.

2. Linear Actuator

The actuator represents one of the most important parts of the system since it provides it with the ability to move the rails in different directions. It can be powered by electricity or a hydraulic system.

It is not a very complex part, and the only purpose is to move the rail in a straight line. Another great thing is that this component is very cheap. Besides CNC machines, we can see this application in campers, pneumatic tools, printers, and other systems.

3. Choose the Right Products

It can be complicated to determine the best option when it comes to linear rails. In that matter, it is essential to learn more about the properties and capabilities of various systems that you can apply.

Before that, create a detailed strategy where you will choose the type of products that you will create with machines, and then focus on getting the suitable additional tools for that.

4. Different Mounting Options

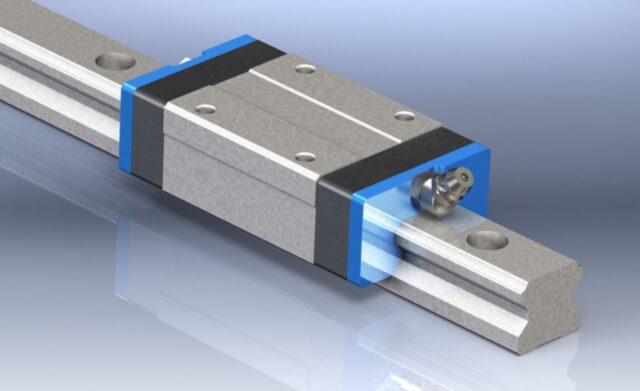

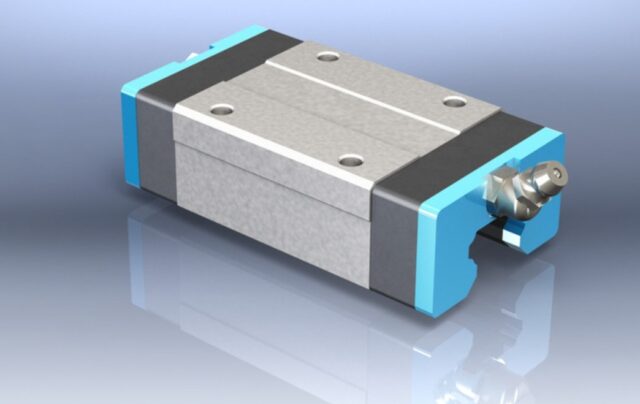

There are different types of these rails, and the most common are multi-blocks and single. When it comes to multi-blocks, they can be used for single or several rails at once. The most important features of single blocks are accuracy and resistance. The multiple clocks are more complex, and they are used in systems that contain two or more rails.

5. Durability

It is always important to pay attention to the quality of tools, especially when you need some for advanced processes and systems used in production lines. Resistance and durability are one of the most important features to look for when buying linear guide rails.

Keep in mind that some processes can be very fast, which will cause higher pressure to different parts, and lack of stability and resistance might result in malfunction or some other issues.

6. Automation

Commonly, many manufacturers are implementing advanced systems where machines can do most of the work. The benefit of that is that you can save a lot of money by having less need for labor. Also, automation provides higher capacity and efficiency in production. The linear rails are essential for automated processes.

Mistakes To Avoid When Buying Linear Guide Rails

First of all, the crucial feature is related to the correct measurement and size of the rails. Also, you can reach higher flexibility if you consider adding some mounting options. With this additional ability, the machine will become able of processing materials in different directions while you are still using a single rail system.

Besides that, always choose these tools according to materials that you will have to treat in the production. That way, you will avoid issues where the machine is not powerful enough to create a certain object. Another common mistake is related to a lack of accuracy in preload determination. Paying more attention to this part provides improved performances of the machine.

Be sure to test some options before you decide to implement them into your production line. The great selection of rails is excellent, but keep in mind that some of them might offer poor performances for certain materials. Also, there can be a difference in time needed to finish some processes, or lack of accuracy, quality, and other potential downsides.

The Bottom Line

There are many advantages of implementing a CNC machine with linear rails into your business. There is no similar option when it comes to speed and quality. Moreover, the benefit is that some processes might require only a single rail. For example, a transportation company.

Also, it is an affordable solution that offers excellent stability and advanced performance. It might sound too simple since the rail is moving only in two directions. However, the challenge can be to set the machine to work at a higher speed while keeping the same advanced abilities.

One of the best ways to determine the best option is to learn more about your requirements and focus on those companies that are well-known as manufacturers of high-quality tools, like Ina Bosch, Nsk, Schneeberger, and more. Moreover, you can always contact an expert if you are not sure about the selection of the right model that you should apply in your production line.

In the end, proper maintenance is important as well. The best way to protect the rails is by keeping them lubricated. The great thing is that a lot of new models have improved systems where the lubrication will be applied automatically. The key is to never rush, and to always have a detailed plan of your project so you can make the right decision.