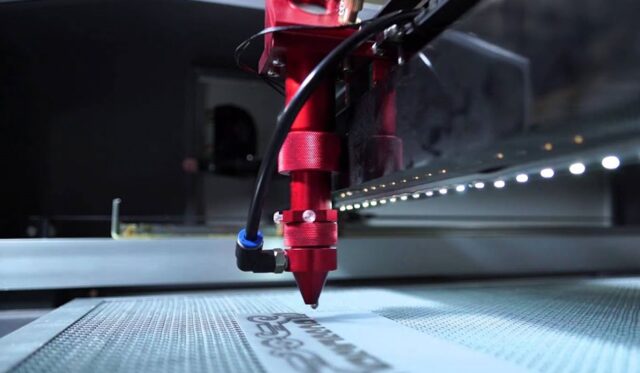

Engravings, markings and even cutting is much easier today than it used to be. The equipment and the tools that we have today are more powerful, they have better power efficiency and they also perform much better. But, there are different types of machines that can do engraving or marking. First, we had those traditional devices that used metal drill bits. But, today, we even have fiber laser machines that can do the same tasks, but faster and better. Of course, there are still some situations where those traditional devices are needed.

However, in this article, I wanted to focus more on laser marking technologies. I want to help people understand this kind of technology better and to ensure that they are investing their money in the right place. Since these types of machines are a very new subject to a lot of people and the technology itself is quite young, these types of guides or articles with tips are needed.

So, here are some of the tips I can give you to help you understand everything you need to know about laser marking technologies.

Page Contents

1. Lasers can be unique in their own way

Many people seem to believe that every laser is the same. But every one of these machines can do the same type of engraving or marking on every material. But, that is far from the truth. Several different factors need to be considered to determine exactly what the machine can do.

For example, one device is able to engrave almost any material. It does not matter whether it is paper or steel. But, some other device is only able to engrave on paper or something similar. It will not do any kind of damage to steel, aluminum, or any other metal.

This is mostly based on the power of the device and the lens equipped with the laser. The lens is used to help focus or diffuse the emitted light. It works quite similarly to the camera. The smaller the hole on the lens, the more focused the light. The more open the hole on the lens, the light is diffused a lot more. This determines the power of the laser. A more focused one will be able to engrave on metal. But, when it is diffused, it won’t be able to damage metal such as steel or iron.

Power is another factor that needs to be considered. The power ratings vary depending on the machine. Smaller ones can have a power rating of just 30W while others can be well over 100W.

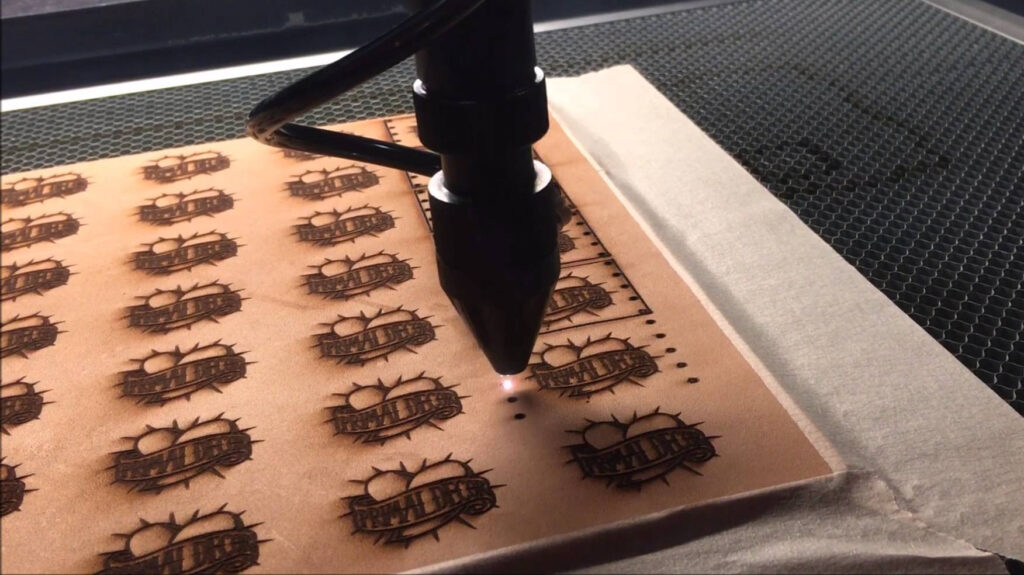

2. CO2/Gas Laser

To understand this technology, you will also have to acknowledge the fact that there are different types of lasers. The most commonly used ones are probably the gas types. In most devices made these days, you will find that the gas is almost always CO2.

So, basically with the help of CO2 or other gases, the light emitted is amplified several times to get to a certain level of power.

This type of laser is so common because it is best used on organic and lighter materials. So, it is not good on steel, aluminum, or iron, but it is great for paper, wood, cardboard, or anything similar. It is also a very affordable option, mostly because it is one of the oldest methods in the industry. So, it is affordable, it is power efficient, it is quite accurate and it is easy to repair. It definitely is the best choice for new businesses.

So, the only disadvantage of the CO2/Gas types is the fact that they cannot cut into harder materials and that they are not able to provide any intricate engravings/markings. For that, you will need to look into other methods.

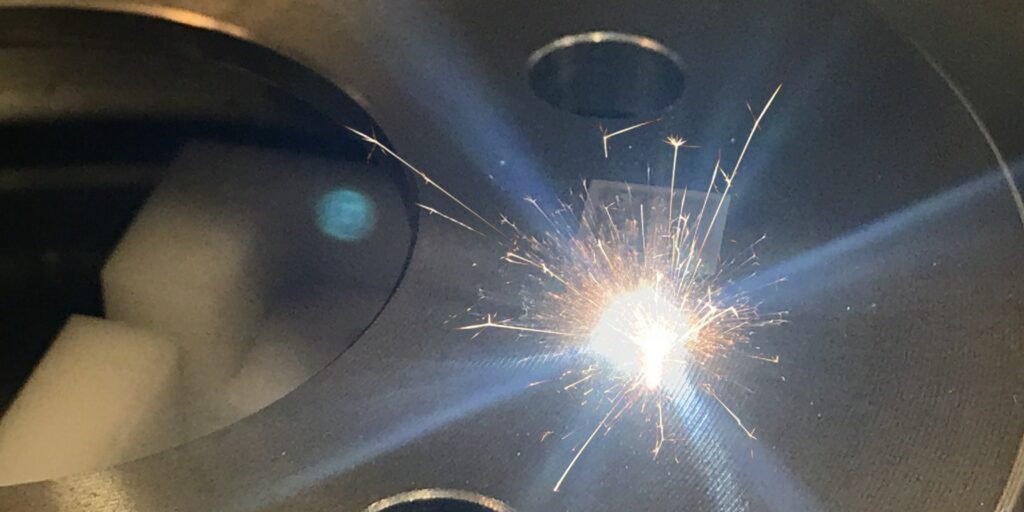

3. Fiber laser

The latest and the newest type of laser that you will see on the market today. With the use of rare earth elements or more commonly referred to as crystals inside of the device, the light emitted from inside is amplified and focused which results in a very powerful beam. This kind of beam can engrave, mark, and cut into almost anything.

Most businesses that plan to work with any kind of metal always go with fiber. Because of its power, but also because it is very versatile. The fiber laser marking machine can withhold the beam for much longer thanks to its efficient cooling system as suggested by www.hispeedlaser.com. It can also pulse at a much higher rate compared to gas machines, making it great for engravings with small details.

These machines rarely need repairs mostly because there are no moving parts. Although, if something does break, the repairs can get a bit expensive. The device itself is a bit more expensive than other options on the market. But, its price is the only disadvantage in my opinion.

4. Solid-State Laser Markers

This is the option that is in-between fiber and CO2/Gas. It has a much better beam quality and precision than CO2, but it is not better than fiber. Also has a much faster pulse rate than CO2 machines which means it is possible to engrave much faster with it. Speeding up your productivity is essential in this industry. Although, again, it is slower than machines equipped with a fiber beam.

Solid-state beams are also quite expensive to repair and are prone to problems because they have multiple moving, mechanical parts.

In the end, which one you decide to use depends on the initial cost. Sure, fiber lasers are better in most aspects, but once you consider the price, maybe the compromise is worth it. It also depends on what kind of work you are planning to do. If you don’t need to have such a high-powered beam, a gas laser might be more than enough.

The laser marking technology and industry is quite complicated and can be difficult to understand at times. But, thankfully, there is tons of information on the internet about this subject such as this article. I hope that these tips will be of use to you.