Small businesses are automating in some form or another at a very fast pace, and this is having lots of implications on the work industry. This is all due to the need to keep up with the pace of development to avoid being left behind by their competitors. But when it comes to embracing the automation process, what are some of the things people have to keep in mind? This level of transitioning is high and requires a lot of deliberations. The following are some of the factors you have to consider when automating your small business.

Page Contents

Application

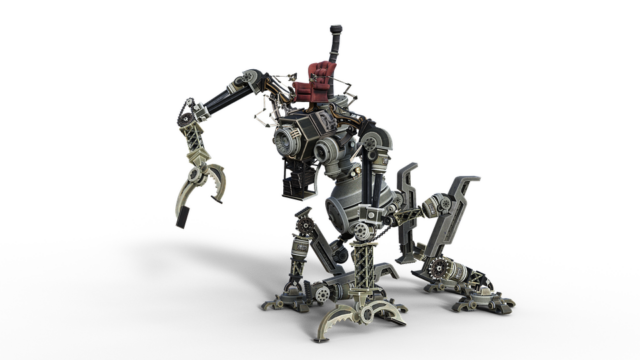

Automating your enterprise is not for show; you must have a purpose for it to begin with since it is not a cheap undertaking. What do you want the robot or the AI application to do? If you are a manufacturer, how heavy are the loads you intend to delegate to the robot? What level of accuracy are you looking for? Will it be working alongside human workers? All these and more are some of the questions you have to ask yourself when looking for an industrial robot because they are built differently, they are not meant for multitasking.

A robotic welding arm, for instance, cannot be used to carry heavy loads and vice versa. Each robot has a specific application, and it would serve you well to stick to that. Click here for more information.

Ease of Programming

Robotic programs are the heart and soul of industrial robots, and if you ever intend to upgrade them or have them perform a particular function better, the program is what you tinker with, not the physical parts. The best industrial robots should not be too complicated for the manufacturers to operate without needing to call the parent companies anytime something goes wrong.

When buying a robot, make sure it comes with a detailed manual that clearly lists all the troubleshooting options that one can perform to get it working as it should. It shouldn’t be a complicated affair requiring a rocket scientist to be flown in to solve even the most minor issues.

The Cost

Automation is one of the costliest transitions any business can ever go through. First, you have to lay off the people who were working for you and that means huge severance packages; you might have to dig deep into your savings. Secondly, you have to procure the right robots; this involves having them customized to your preferences and the working space that you have, which takes money. Then there’s the issue with training the few workers left behind to operate them.

All the training, the shipping of the robots to the factory, the actual installation on the floor of the manufacturing plant,, and other unforeseen things will set you back a significant amount of money. Make sure you have enough in your bank account before embarking on automation.

Safety Concerns

The current industrial robots may be the most advanced but they are still machines that are under development; they have not been perfect to the point where they can be left to run things on their own without some human involvement. For this reason, they have to conform to all the safety standards of the manufacturing plant. If you do choose to go with collaborative robots, for instance, you have to ensure that the safety of the workers is prioritized. This involves doing tests beforehand to fish for glitches that may lead to accidents. Ignoring the safety parts of automation will land you in trouble.

Versatility

Industrial robots are very task-specific. Welding robots deal with welding, painting ones deal with painting, and so on. However, there are some that can be programmed to deal with more than one task that doesn’t require a high level of sophistication. You could have a pick and place robot that also handles the sealing of packages before transferring them to another area. This is the kind of multitasking that would get you the best value for your money. If one robot can do the same tasks that would have been handled by a bunch of different people, then you’ll end up saving a significant amount of money in the process.

The Reputation of the Brand

There are a number of robot manufacturers who have been in the game for long, gaining valuable experience that enables them to constantly create top-of-the-line robots and their accompanying software. When buying a robot for your venture, pay attention to the brand reputation of the company behind it. Where robots are involved, the bigger the brand, the better their products because this translates to better technologies at their disposal. They may cost an arm and a leg, but you’ll be getting a product that has been tried and tested, has good support, and with readily available spare parts.

Conclusion

We are smack in the middle of the robotics age, and their use is only going to accelerate from this point onwards. It is no longer a debate of whether you should get industrial robots for your business; it has now become a matter of when because everybody is moving in that direction. There are more improvements needed to make them better, but as far as manufacturing is concerned, automation is the best way to ensure the continued survival of your business.