If you’re new to the world of CNC machining, there’s a lot of terminology that you’ll need to learn. This article will introduce you to some of the basic terms used in CNC machining, so that you can better understand the process.

Page Contents

Basic CNC Machining Terms

Every machinist should have a basic understanding of CNC machining terms. Here are some of the most commonly used terms in CNC machining:

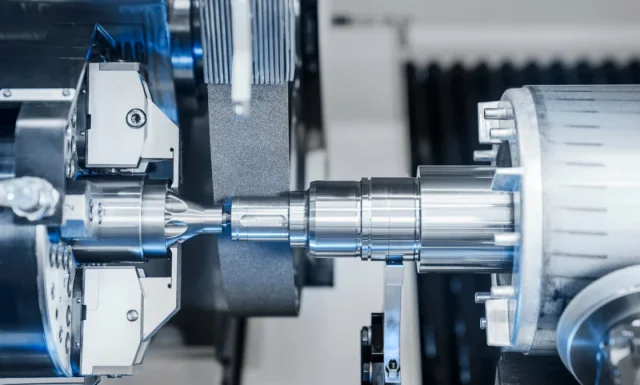

- CNC machine: A computer numerical controlled (CNC) machine is a machine that is controlled by a computer. The computer controls the movement of the machine’s tools and allows for very precise cuts and designs.

- G-code: Is a programming language that is used to control CNC machines. It tells the machine what movements to make and how fast or slow to move.

- Toolpath: Is the path that the tool takes as it cuts through the material. This can be programmed into the CNC machine so that the same path is followed every time.

- Spindle: Is the part of the CNC machine that holds and spins the cutting tool.

- Feed rate: Is the speed at which the cutting tool moves through the material. This can be programmed into the CNC machine so that the same speed is used every time.

CNC Machining Operations

Computer numerical control (CNC) machining is a process that uses computer-controlled machine tools to create parts with a high degree of precision. CNC machining can be used to create a variety of different parts, from simple objects like coins to complex objects like aircraft engines. CNC machining is often used in the aerospace, automotive, and medical industries where parts need to meet very tight tolerances. In addition to high precision, CNC machining can also be used to create parts with very intricate shapes.

There are a variety of different CNC machining operations that can be used to create parts. Some of the most common operations include milling, turning, and drilling.

– Milling is a common CNC machining operation that involves removing material from a workpiece using rotating cutting tools. Milling can be performed on both horizontal and vertical axes. CNC routers are often used for milling operations. A CNC wood router is used to create parts from wood, while a CNC metal router is used to create parts from aluminum, brass, and steel.

– Turning is another common CNC operation that involves rotating a workpiece on a lathe while cutting tools remove material. Turning can be performed on both cylindrical and non-cylindrical objects.

– Drilling is a CNC operation that involves using a drill bit to create holes in a workpiece.

CNC Grinding Machines

CNC grinding machines are used in a wide variety of industries for fabrication and manufacturing. As with any type of machinery, there is a certain amount of specialized terminology associated with these machines. Here are some of the most important terms to know when working with CNC grinding machines:

– Abrasive: A material used for grinding, such as aluminum oxide or silicon carbide.

– Belt grinder: A type of grinder that uses a rotating belt covered in abrasive material to remove material from a workpiece.

– Centerless grinder: A type of grinder that does not use a spindle. The workpiece is instead supported by a guide wheel and regulated by a regulating wheel.

– Cylindrical grinder: A type of grinder used to create cylindrical shapes. The workpiece is supported between two points and rotated while abrasive material is applied to it.

Conclusion

The world of CNC machines can be a little overwhelming at first, but hopefully this article has helped to demystify some of the basic terminology. As a machinist, it is important to have a good understanding of the different parts of a CNC machine and how they work together to create the final product. With this knowledge under your belt, you will be well on your way to becoming a master machinist.