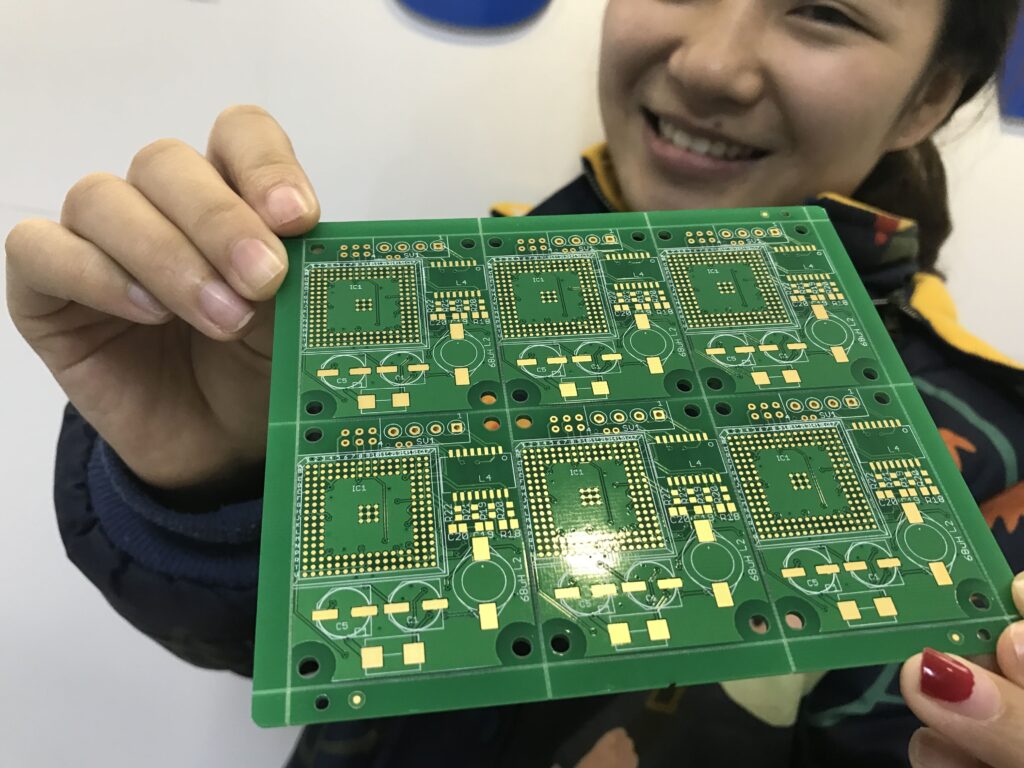

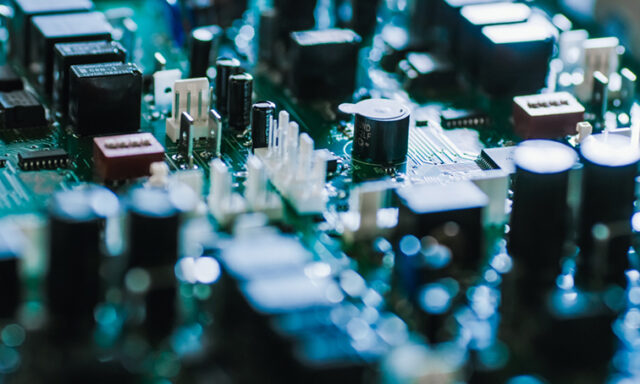

No matter what type of electronic device you’re trying to produce, you’ll have to deal with PCBs. These small components are found in almost all electronics, from calculators to computers. They’re what essentially controls the electric current and “tells” it where to go. Without PCBs, there would be no functional electronics.

If you want to learn a bit more about how these are made, you’ve come to the right place! In this article, we’ll tell you everything you need to know about PCB manufacturing.

So, without further ado, let’s get to the bottom of it!

Page Contents

Tip number 1: Know the materials

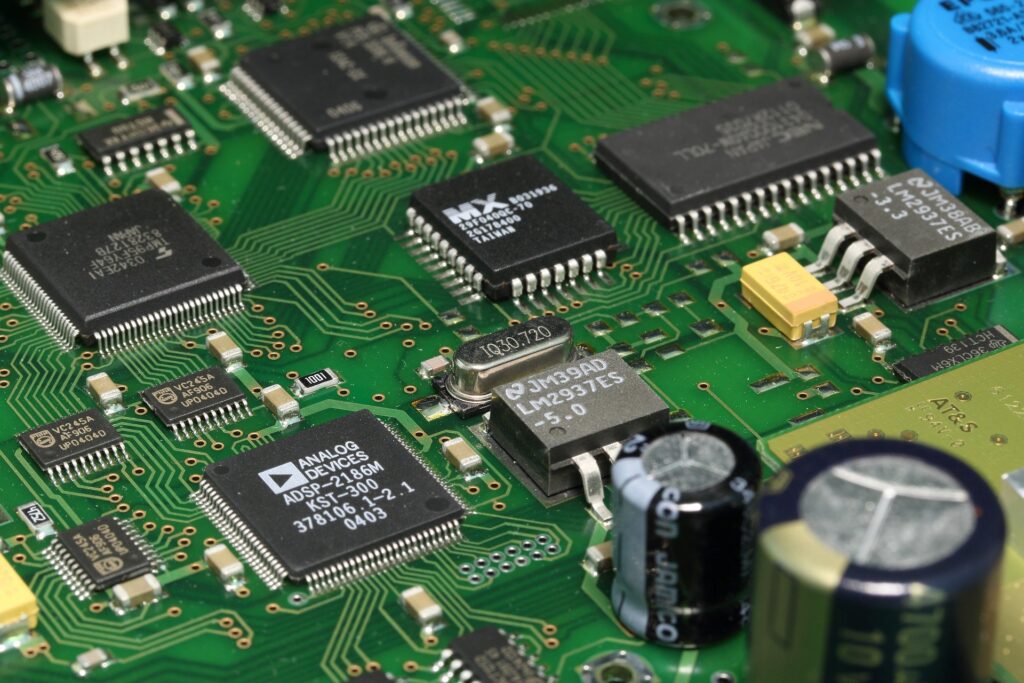

Printed circuit board substrates are most commonly made out of fiberglass with a copper foil on one or both sides. The copper is covered with tin-lead, and nickel.

Overall, there’s not a lot of raw material used for manufacturing the PCBs, but it’s still important to learn about it. The entire process is quite complicated, so we’ll only cover the basics in this article. If you want to learn everything in detail, then we recommend you find some online publications, manuals, or books that cover the topic more thoroughly.

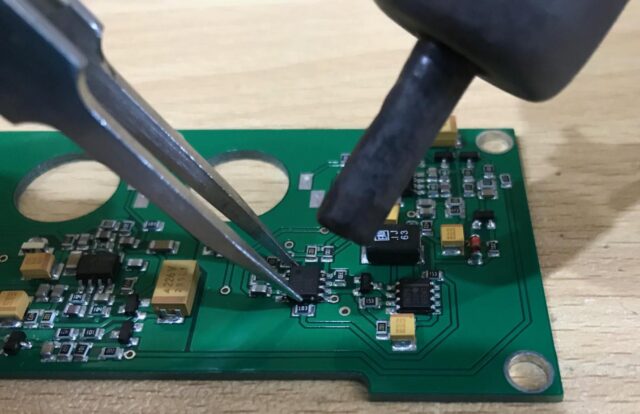

Tip number 2: Know the process

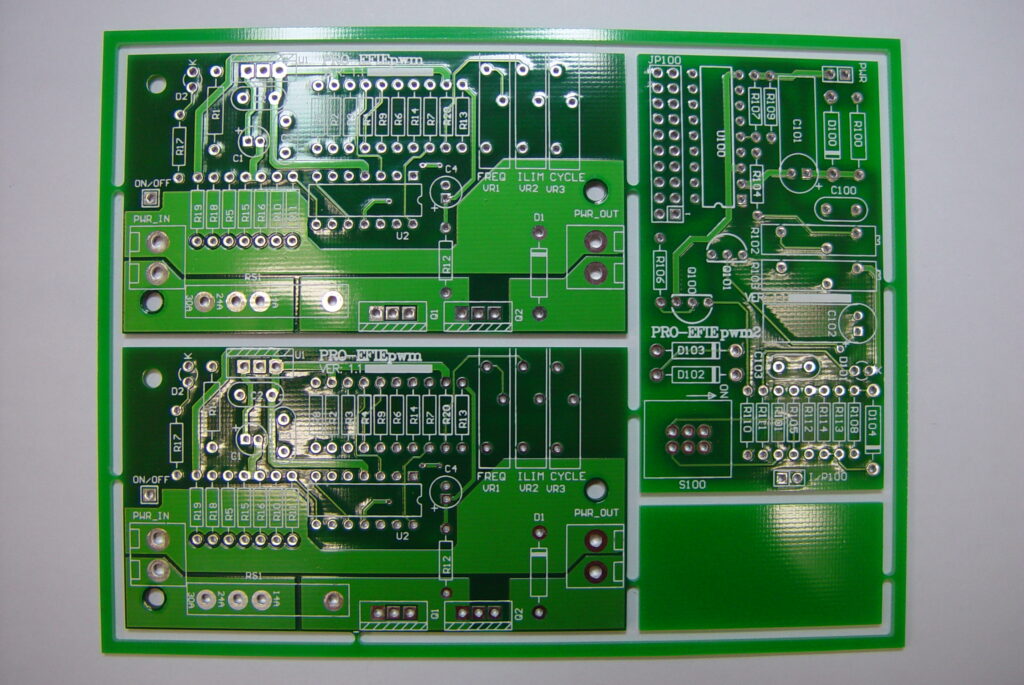

Once we have the board, we’re printing its future “look” by using a plotter, which is a special type of printer used by PCB manufacturers. After that, we’re going to remove the excess copper with the use of specific chemicals. Then, the circuit board needs to be drilled to make the holes that will connect the upper and the lower print. The holes need to be metalized, and the entire board is covered with a protective layer, which prevents short circuits from happening.

Of course, as we mentioned before, this is just a brief explanation of a very complex process that requires a lot of time and effort to be understood properly.

Tip number 3: Understand the design

Before you begin building your PCBs, you’ll have to come up with an adequate design. Of course, the design will solely depend on your needs and goals, so we’re going to talk about ways to make it cost-effective.

First of all, the more complex it is, the more it will cost you. While that’s easy to deduce, the question that has to be asked is: What is it that makes a design complex? Well, the main factor is the number of components used. The more parts you have, the more difficult it becomes to assemble. Other than that, you should be mindful of the component type. We recommend looking for standard integrated circuits for maximum cost reduction.

Of course, depending on your needs, you might be forced to go with a complex design. If that’s the case, consult with an industry professional who can help you find an affordable solution.

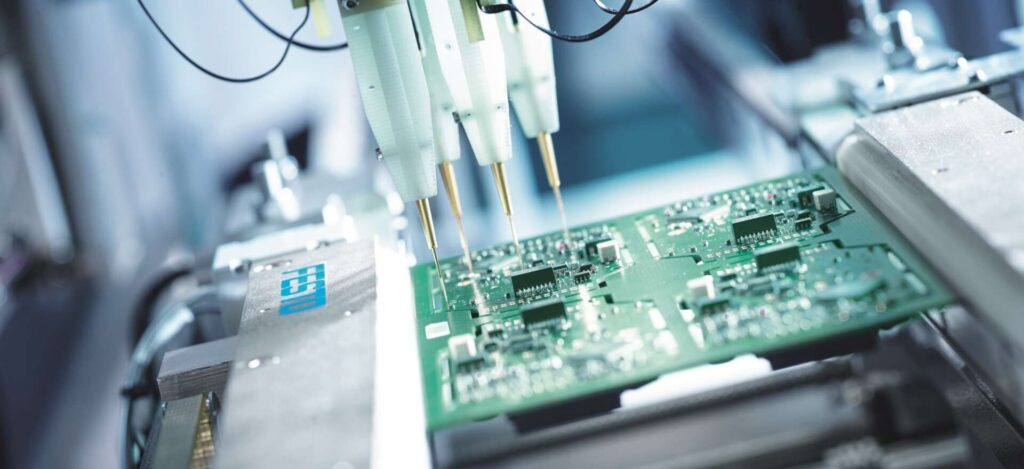

Tip number 4: Talk to your manufacturer

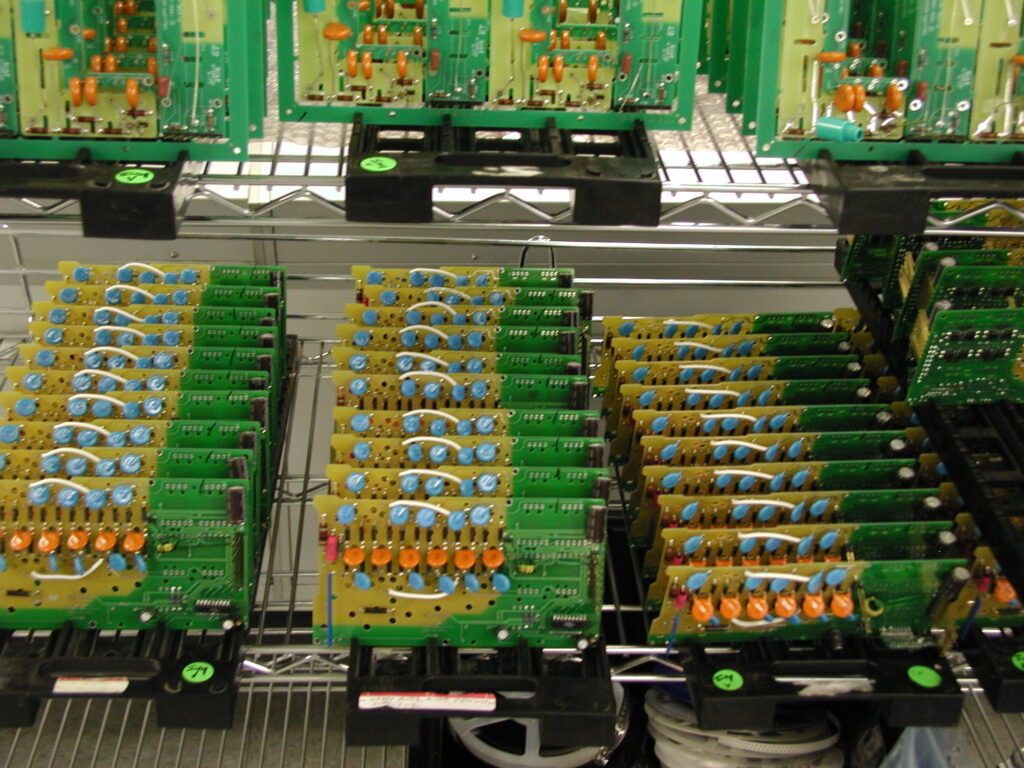

The fastest way to understand the PCB manufacturing process is by consulting with a manufacturing service or a factory. They’ll be able to give you advice and walk you through the process. You’re always better off leaving these matters into the hands of professionals.

Of course, make sure to look for experienced and reliable manufacturers for this task. Most of the well-known ones such can be found in China, which is famous as “The world’s factory”. You can click here to find an example of a manufacturer that offers the harness assembly and box build assembly services.

Whatever you do, make sure to ask the manufacturer as many questions as you can. The more you know, the easier it will be to negotiate the final price.

Tip number 5: Find the right literature

If you’re interested in learning all the complicated details of the PCB manufacturing process, you can find all the information you need online. Various web-articles and publications explain the process in a lot of detail.

If you prefer learning from books, get something like the “Manufacturing Assembly Handbook” by Bruno Lotter for example. Luckily, there’s a ton of resources from where you can learn about the process in as much detail as you want.

As we mentioned before, your best bet is to ask an industry professional about it. Visit a factory, and politely ask them if they have a manual you can read. Whatever you do, remember to learn as much as you can before you invest your money into the entire process.

Tip number 6: Know the lead times

How much time does it take to get a PCB produced? Well, typically, it’s about a week, but it all depends on the complexity of your design and the amount you ordered. The best way to learn this is to ask your manufacturer directly.

If it’s your first time manufacturing PCBs, then you should know that the manufacturing process shouldn’t take more than a month (and that’s quite stretched already). Of course, assembling and shipping product are also a factor. Assembling can take up to two weeks sometimes, depending on the complexity of the assembly. If you’re shipping from overseas, keep in mind that due to the COVID19 restrictions, you’ll probably have to deal with a lot of delays.

Overall, knowing the lead times are essential to understanding the PCB manufacturing process because it shows just how layered the entire process is. It’s much more than just raw production, it takes some work on your part too. Of course, once you make an order, your only job is to wait. Still, it’s important to know how much time you’re going to spend waiting, don’t you think?

The takeaway

Understanding the PCB manufacturing process is not an easy task. The specifics of the process cannot possibly fit into a web-article. That’s why companies and individuals in the industry usually spend years on training and research before starting to produce the components. Of course, if you’re in a need of such services, make sure you learn as much as you can since it’s the best way to ensure you get the results you want.